Aluminium system for warehouse and production environment

Constructions using aluminium profiles are widely used in warehouse and production facilities. For instance, many machines are enclosed by protective structures made from aluminium. Another common application is ergonomic solutions, including workstations, footrests, and movable cabinets.

Aluminum is a highly versatile material that is easy to work with, offering exceptional flexibility, particularly during assembly.

Our colleague Niclas has three specific tips on how to optimize the assembly of your aluminium construction. Among other things, he advises on the importance of modern CAD drawings in 3D, and the advantage of partial drawings instead of general drawings.

Today's flexible design options, for example solutions with aluminium profiles, enable ergonomic solutions even in production and warehouse facilities. The key lies in creating an adaptable workstation, which can be adjusted according to the individual's needs.

Read more about ergonomic industrial workplaces

One of the great advantages of aluminium enclosures, apart from being naturally rust and maintenance free, is that they are flexible and easy to install and modify. They can be delivered in sections, assembled and adjusted on-site. The panels installed in the frame are available in a variety of materials and can also serve as noise protection when sound-absorbing panels are used.

More about guarding and protective walls

A machine guard made from aluminum profiles combined with various types of panels effectively protects both personnel and the surrounding environment. Sometimes there are situations where the machine itself needs protection from external contaminants, and in such cases, machine guards also play a crucial role.

We tell you more about machine guarding

How do you operate several belt conveyors synchronously? There are many answers to this. The important thing is to start with a proper needs assessment. We provide examples of how two belt conveyors can be synchronized using a synchronizing shaft. Additionally, we explore a solution for operating four belt conveyors simultaneously.

Read about parallel operation of several belt conveyors

Aluminium has a low density and is naturally stainless, on the other hand steel is a relatively cheap material. In general, this does not apply to stainless steel, which is usually more expensive than aluminium. From the designer's point of view, the flexibility of aluminium systems is often a winner.

Read the design engineer's views on aluminium/steel stands

One or our Danish colleagues tells us about a customer project where there was a great need for a clean and dust-free environment. Enclosures of aluminium profiles were used to effectively isolate part of the warehouse. Delivered as a kit made it easier to transport and reduced the cost of shipping.

Read more and see pictures from the project

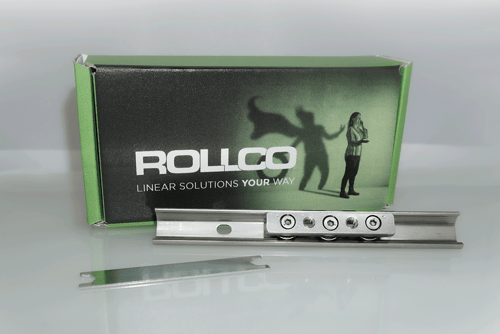

Order our demo kit with rail and slider with rollers and see how C-Rail looks and works. The C-Rail is a relatively simple product, which can solve advanced applications and is also a cost-effective solution. The system is available in both stainless and galvanized steel, which makes it well suited for some demanding environments.

CONTENT

- Aluminium frame structures, easy ways to improve your assembly process

- Ergonomic workstations in a production environment

- Machine guarding and protective walls

- Protection for man and machine

- Synchronous operation of belt conveyors

- Aluminium frames versus steel frames

Customer case

Order a sample kit