Linear systems and aluminium systems – How to improve your construction

Creating an optimal design that meets the requirement specification and is cost effective requires some thought. But there are things you can do to simplify your construction work, both for linear systems and aluminium systems. We have gathered information about everything from how to solve misalignment problems and how to facilitate the construction process to how to choose the correct fastener for your aluminium construction.

In the case of a linear movement, the rails are mounted parallel and level with each other. It is a construction that must be very precise – it involves tolerances down to hundredths of a millimetre. Problems with deviation in parallelism thus arise when the mounting surfaces are not completely precise or rigid, and it can take a long time and cost a lot of money to get it right. In addition, they cause wear and tear, which drastically reduces the service life. Parallelism and angle problems almost always occur with linear movement. Therefore, we offer a product that easily solves the problem already at the construction stage. It combines a guiding and a floating rail and can accommodate up to four millimetres in parallelism variation.

Constructing an aluminium stand is primarily about creating a functional solution. But it is also about optimising the construction to ensure the assembly is simple and cost-effective without sacrificing quality. What kind of fastener you choose, slot depth on the profile and different types of feet are some things you need to consider when constructing an aluminium stand. Our fitters Henrik Rönn and Niclas Hellgren give five tips about ensuring that your construction can be quickly assembled and works optimally.

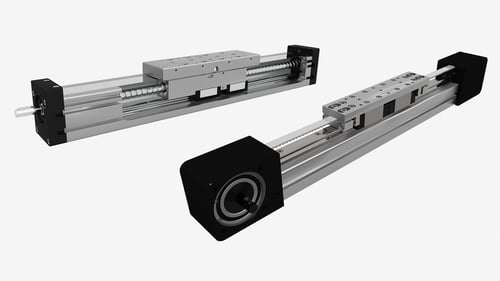

A ball screw driven and a timing belt driven linear unit have different advantages and strengths. Which one you should choose depends on your application's requirements: speed, accuracy, tolerances etc. The ball screw and timing belt have different characteristics that can be beneficial in their way. The application requirements determine which is the best fit. To simplify, if you need high repeatability, stiffness and force, you should choose the ball screw. A timing belt driven linear unit is the better choice if you need high speed and long movements.

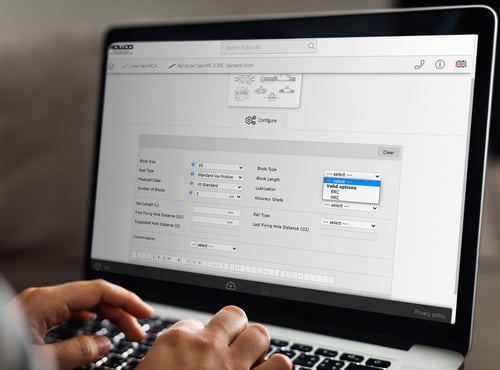

Constructing a linear system is not always easy. There are some common problems and pitfalls to fall into. At the same time, there are some things you can take advantage of and aids that make the process easier. One of the more common problems when designing a linear system is getting access to CAD files. Without a CAD file, the project risks stalling because it will be difficult to move forward. Therefore, it is important to choose a supplier with an extensive CAD library. To shorten the development work, it is also important to be able to quickly present a concept that shows how to think simply and clearly. Here, too, the availability of CAD files is of great importance. Another good idea is to get a price indication early in the project to find a good balance between price and performance. When you know what different types of solutions cost, choosing one is much easier. This makes it faster to reach the goal, and you can avoid a lot of retakes and iterations.

According to Daniel Stifors, sales representative at Rollco, many factors determine which accessories you need to construct a well-functioning linear rail system. To achieve a long service life and little need for maintenance, you may need to choose a preloaded slider or a slider with extra seals. It depends, among other things, on factors such as the surrounding environment and special application requirements. There are various accessories to lubricate and protect the linear rail guide, including different types of seals and end caps for the carriages. In environments where it may be difficult to access to lubricate your rail guide, a self-lubricating seal is suitable. If the surrounding environment is stressful, the rails can be provided with different surface treatments that extend the service life. In addition to the most common ones, such as nickel plating and chrome plating, special treatments can provide extra high corrosion protection.

Which fasteners are preferable for different aluminium constructions? Here are some rules of thumb to simplify the choice. When you are building an aluminium structure, it is easy to get confused when choosing fasteners. Which one suits what, and what advantages and disadvantages do they have? There are a few different types of fasteners, but here we focus on the four most common, Standard, Central, Universal and Automatic. They all have pros and cons, depending on what your aluminium construction is for. A standard fastener is simple, a central fastener is discreet but sensitive to vibration, a universal fastener is strong and an automatic fastener is flexible.

If you want to test what fits together, you can order our free sample kit! It consists of three types of aluminium profiles and four different variants of fasteners. With them, you can tangibly try out which combinations are best for your construction.

CONTENT

- Solve problems with misalignment easily

- Think in advance when you construct an aluminium stand

- Advantages and disadvantages of ball screw or timing belt in a linear unit

- Avoid the most common problems when designing linear systems

- Accessories and options for linear rail guides – when to use what?

- Choosing the right fastener for your aluminium construction

.jpg?width=500&height=334&name=_77A4881%20(alu-standard).jpg)