The right linear guide for your application

There are many factors you need to consider when designing a good linear guide system for your application. Among other things, you have to consider deviations in parallelism, make a proper analysis of the requirements, choose an optimal drive and the right type of linear rail guide. Read more about what you need to think about below.

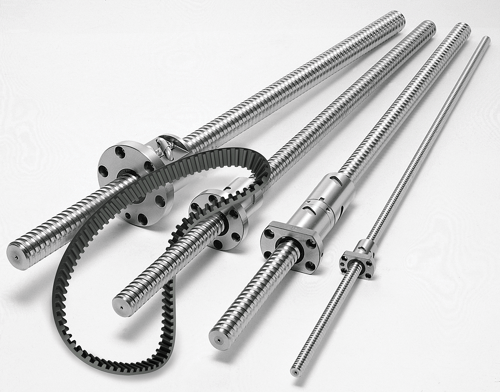

The choice between ball screw and timing belt is determined by which properties are most important for your linear drive. Do you need to prioritize accuracy or speed? Do you have limited space? Is it important that the application requires minimal maintenance? There are a number of different areas where the properties of the ball screw and timing belt are important for the linear movement. Depending on the application requirements, they have different advantages. Simply put, the ball screw is good if you need high repeatability, stiffness and power, while the timing belt is good if you need high speed and long movements.

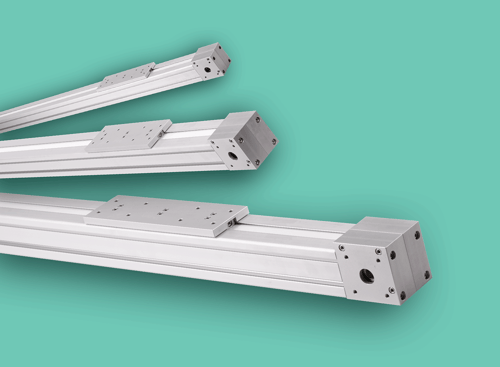

When designing a linear motion application, you can either choose to build the unit yourself using separate components or choose a complete unit ready for installation. There are advantages and disadvantages to both, depending on the conditions of the application. If you choose to use separate components, you must integrate the drive yourself, something that is already in place when you buy a ready-made linear unit. The advantages of separate components are that you can design your linear unit exactly as you want it.

Completely avoiding problems with parallelism in linear motion applications is almost impossible. However, there are ways to handle them so that you can facilitate the installation of the rail guide and in the long run reduce the wear on the rails. Linear guides with recirculating balls have high precision and the capacity to handle heavy loads in all directions with high accuracy and motion control. Though, in some situations and applications, these strengths can also create limitations.

There is a discussion about which solution is best in linear guides, whether balls or rollers give the best results. But the fact is that the question is wrongly posed. As always with linear motion, the answer to any question starts by looking at your application. It is the application and the goal you have with it that determines which solution is best. It is about what needs you have in terms of stiffness, precision, accuracy and load, among other things. In other words, the choice between balls and rollers depends on what you want to achieve.

In most cases, a linear movement takes place in a straight line between two points or in a circular movement. However, some applications require a combination of straight lines and bends in a curved linear motion. A curved movement is normally either made up of uniform curves, like a 90 or 180-degree bend along with straight stretches, or a mixture of different bends, more like a curved line. The former is often used in connection with various forms of conveyor belts that transport parts during assembly or quality control. The second variant is most often used when something needs to be transported along a straight line but where different bends are required to avoid obstacles.

There are many different factors that come into play when creating a telescopic linear movement. Whether it is horizontal or vertical and what the surrounding environment looks like are some of them. It is therefore wise to first make a thorough assessment of all available relevant information. Water, humidity, sawdust and temperature for example, are important for material selection and possible enclosures. But also, limitations in the physical space, if the telescopic linear movement is to be enclosed, have an impact on strength and function.

A manufacturer of packaging machines wanted to reduce the number of suppliers of linear components. They put them all through a life-time test where the slider was made to run continuously until the point where it broke. Rollco's rail guides survived the longest, thanks to the steel reinforcement plates on the sliders.

There are many parameters and factors to consider when choosing the right linear system for your application. To facilitate your assessment and give you guidance, we have compiled a guide with 10 tips on how to choose the right solution.

CONTENT

- Linear drive with ball screw or toothed belt?

- Advantages and disadvantages of using complete linear units

- How to solve misalignment and parallelism errors in linear movement

- What is best? Linear guides with balls or rollers?

- How to design a curved linear motion

- Create telescopic movements that last

Customer case

Download